TOMRA has unveiled an AI-based expertise for upgrading wrought aluminium scrap and producing excessive purity fractions, GAINnext, designed to be used by aluminium scrap processors and recyclers.

Apparently, this growth represents the primary utility of GAINnext within the metals trade. The brand new expertise recovers low alloy solid from the wrought fraction and reduces alloying parts akin to silicon. GAINnext enhances TOMRA’s X-TRACT sorting answer which separates based mostly on atomic density.

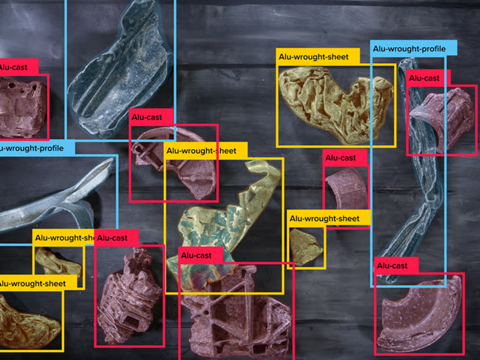

X-TRACT options X-ray Transmission (XRT) expertise and initially types shredded blended non-ferrous metals (Zorba) to supply high-purity aluminium scrap (Twitch), then removes excessive alloy aluminium solid and high-density wrought aluminium to additional refine the Twitch. TOMRA says this course of yields a high-quality fraction, containing each wrought aluminium and minor quantities of low alloy solid, which different at present out there sorting strategies can’t absolutely separate.

By integrating GAINnext into the sorting course of after X-TRACT, the corporate says a pure wrought fraction will be achieved. Utilizing RGB cameras GAINnext reportedly processes tens to a whole bunch of 1000’s of photographs per millisecond, ‘perceiving’ and ‘classifying’ supplies by form, measurement and dimension with distinctive accuracy.

The system goals to imitate human imaginative and prescient however with superior pace, facilitating excessive throughput sorting of as much as 2,000 ejections per minute. TOMRA provides that the wrought fraction recovered by GAINnext will be additional refined utilizing its AUTOSORT PULSE system which employs laser-induced plasma spectroscopy (Dynamic LIBS) for exact identification and sorting of various alloy varieties.

Final October Professor Edward Kosior, founding father of Nextek and NEXTLOOPP, advised us concerning the firm’s collaboration with TOMRA to make use of AI expertise to make recycling processes extra environment friendly. He stated that by offering a sorted food-grade PP PCR stream, TOMRA’s AUTOSORT with GAINnext can speed up the availability of food-grade rPP by way of the NEXTLOOPP decontamination course of in recycling operations globally, with out additional delays related to new label or marker necessities.

In the identical month, Digimarc Corporation launched its Digimarc Recycle sortation software, implementing Graphics Processing Models (GPUs) to cut back prices in comparison with compliant {hardware} and improve accessibility for recycling and waste sortation services worldwide. The software program identifies covert digital watermarks printed onto product packaging and linked with a cloud-based repository of product attributes akin to packaging composition, meals or non-food grade plastic, beauty and hygiene-grade materials, product variant, model, and SKU.

In the event you preferred this story, you may additionally get pleasure from:

The ultimate guide to the Packaging and Packaging Waste Regulation in 2024

How are the top brands progressing on packaging sustainability?

Sustainable Innovation Report 2024: Current trends and future priorities

Everything you need to know about global plastic sustainability regulation